What is Formative Manufacturing.

Formative manufacturing, also known as shaping or forming processes,

is a broad category of manufacturing techniques where a workpiece is shaped into

its final form without removing any material. It's like molding clay with your hands to create a specific figure.

Our offerings

Plastic Injection Molding

- It is one of the best sought-after technologies for continuous production of plastic and over-molded components

- It can produce thousands to millions of parts from a single tool that helps amortize the cost of products

- There a variety of product finish options:

- Machined like

- Shiny

- Semi-gloss

- Matte

- Textured finish

- Our value-added services include

- Mould design

- Mould maintenance

- Mould flow analysis

- Material recommendations

- DFM analysis & reporting

- Coloring options and color matching

- Materials:

- Plastics- ABS, Polycarbonate, Nylon, POM(Delrin), Polypropylene,

HDPE, LDPE, Polyurethane, PC-ABS, PVC, Polystyrene - Additives- Flame retardants, Plasticizers, Colorants,

Glass fibers, etc.

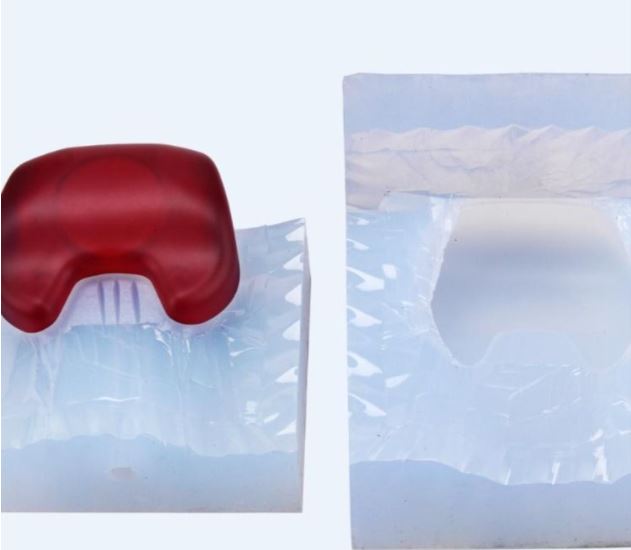

Urethane Casting/Soft Molding

A soft molding tooling technology, this is highly recommended for options

alternate to or before injection molding where the end-use parts are close to the

final commercially viable product with lesser technological debt

- Materials:

- 4 grades of ABS

- 2 grades of PP

- 30% glass filled nylon

- Rubber

- PC-ABS

- Maximum machine volumes up to 1000 mm3

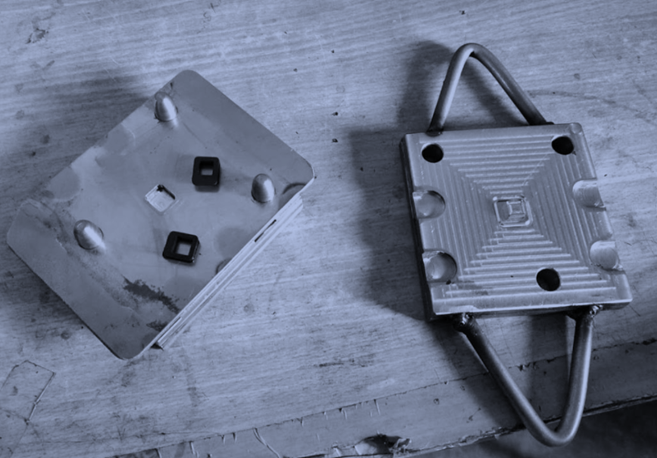

Investment/Die-Casting

- It is the go-to choice for all metal and alloy components

that need continuous production - Our value-added services:

- Mould design

- Mould maintenance

- Mould flow analysis

- Material Recommendations

- DFM analysis & reporting

- Precision machining

- Coloring options and color matching

- Materials:

- Aluminum, Zinc, Magnesium

- Brass, Bronze, Copper

Compression Molding

- A manufacturing technology that is helpful

in production of flexible parts such as gaskets,

O-rings, seals, weather strips, etc. - Our Value added services

- maintenance

- Material Recommendations

- DFM analysis & report

- Color options for rubber material

- Sample verification

- Custom compound mixing

- Tool design and manufacturing

- Multi-material molding

- Materials

- Natural Rubber, Neoprene

- Polyurethane, Styrene(SBR)

- EPDM, Fluoro-Silicone

- Nitrile(NBR), Silicone