Contract Manufacturing

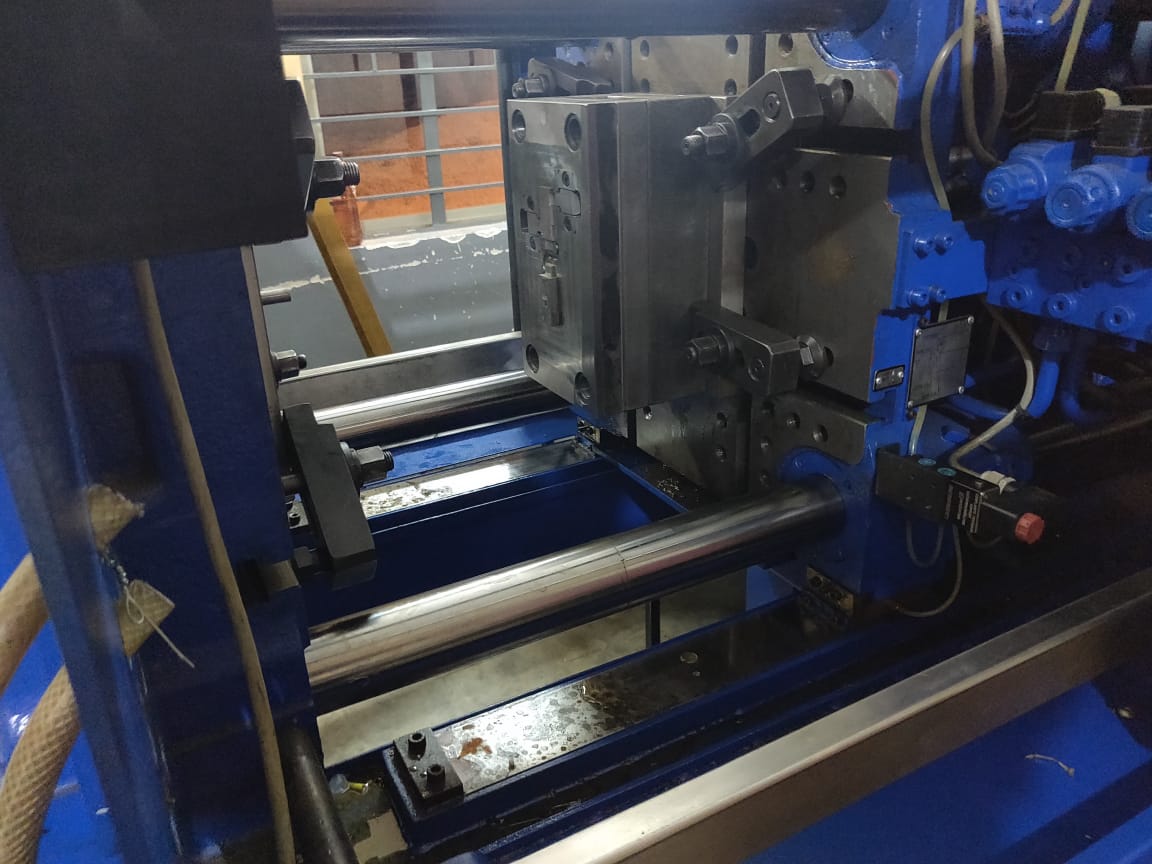

Plastic Injection Molding

- A network of 12 machines.

- Tonnage ranging from 50 – 660T handling.

- Component molding capacity is 0.5 to 1200g

Specialty processes like:

- Insert molding, Over molding, Plastic welding, multi-cavity molding, family molding & Molding with engineering plastics

CNC Machining

- A network of 17 machines

- CNC milling max. machine volumes of 820*510*510mm

- CNC turning max diameter of 500mm and max. length of 1000mm

Fabrication

- A network of 16 manufacturing partners.

- Highly capable of making products through Laser/Plasma/WaterJet cutting, MIG/MAG/TIG welding, Spot welding, CNC bending, Shearing, Cutting, etc.

Die Casting

- A network of 5 cloud manufacturing partners.

- Capabilities in both Gravity Die casting and Pressure Die casting.

- Machine tonnage ranging from 120 to 800 tons

- Component weight ranging from 6g to 2000g

Urethane Casting

- A network of 4 machines of upto 1000mm3 capacity

- Capabilities of producing components ranging from as small as 20 mm to as big as 300mm in length

Compression Molding

- A network of 10 machines

- Capabilities of producing components ranging from as small as 2mm thick O-ring/ seals to 50mm thick gaskets and other flexible materials

CNC Machining

- Capability of providing 15000+ machining hours per month

- State-of-the-art machine tools and turrets, continuous production centers

- Material handling capabilities:

- Metals- Aluminium, Stainless Steel, Alloy Steel, Mild Steel, Tool Steel and Brass

- Plastics- ABS, Polycarbonate, Nylon, POM(Delrin), PEEK, PMMA(Acrylic), Polypropylene, Polyethylene

Plastic Injection Molding

- It is one of the best sought-after technologies for continuous production of plastic and over-molded components

- It can produce thousands to millions of parts from a single tool that helps amortize the cost of products

- There a variety of product finish options: As machined, Shiny, Semi-gloss, Matte, Textured finish and so on...

- Our value-added services also include Mold design, Mold maintenance, Mold flow analysis, Material Recommendations, DFM analysis & reporting, Coloring options and color matching

- Materials:

- Plastics- ABS, Polycarbonate, Nylon, POM(Delrin), Polypropylene, HDPE, LDPE, Polyurethane, PC-ABS, PVC, Polystyrene

- Additives- Flame retardants, Plasticizers, Colorants, Glass fibers, etc.

Die Casting

- It is the go-to choice similar to Plastic Injection Molding, for all metal and alloy components that need continuous production

- For different finish options, the products need to be selectively post-processed using CNC machining, Polishing, Shot blasting or Vibro polishing

- Our value-added services also include Mold design, Mold maintenance, Mold flow analysis, Material Recommendations, DFM analysis & reporting, Precision machining & finishing of molded components

- Our value-added services also include Mold design, Mold maintenance, Mold flow analysis, Material Recommendations, DFM analysis & reporting, Coloring options and color matching

- Materials:

- Aluminum, Zinc, Magnesium, Brass, Bronze, Copper

Printalytix is customers’ preferred choice for

Contract Manufacturing

We provide a Comprehensive Production Engagement Program (CPEP) tailored to your organization’s requirements and priorities

Complete ownership of quality with us and Go-to-Market focus with you

Excellent Application engineering & DFAM support

Efficient tracking and delivery mechanism